09:00 AM

5 Ways an iPad Can Improve Risk Engineering

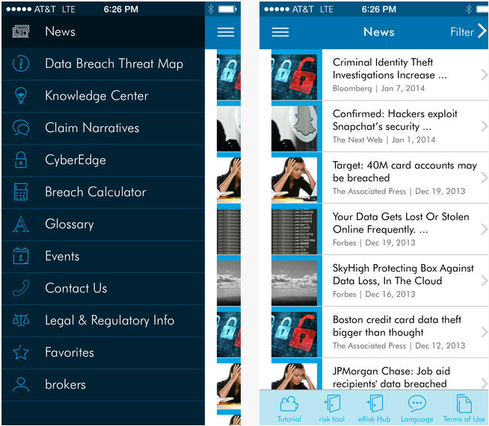

Consider the rapid implementation of iPads and tablets into business operations worldwide. The iPad was released to the market in 2010. Since then, more than 200 million iPads -- not to mention other tablet brands that have made it to market -- have been sold. In such a short period, tablets have become indispensable in many business operations. The global risk engineering team at XL Group is no exception. Last September, XL's global team of more than 150 risk engineers was introduced to the new Risk Engineering iPad Field App.

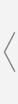

Risk engineers are the eyes and ears of a property underwriting team. They visit property clients to collect information on the sites that a carrier insures. Today they collect that information with this first-of-its-kind iPad-based tool and then upload it electronically. Previously, they collected and reported risk engineering data by taking notes on paper, which were later entered into laptops and sent to underwriters. A process that once took days or weeks can now be done in hours. The tool also lets risk engineers enhance their field notes with site photos or voice recordings. They can even take notes with a speech-to-text capture feature. All this makes the risk assessments even more robust and informative for our underwriters, who must evaluate and price the risk appropriately.

Our iPad risk assessment tool is certainly helping our risk engineers streamline some of their processes, but it's also providing some very cool opportunities for our clients to reap more from their visits. Here's how.

1. We can share more information faster.

Direct input saves time but also speeds up delivery. Risk engineers can share what they report in their risk assessment more quickly. XL uses a tool called MyAnalysis. Clients also have their own safety guidelines that risk engineers need to know. They can now keep this information close on hand, customize visits based on the client's information, get to know client operations better, and help serve their needs more effectively. Risk and facility managers benefit from the immediate feedback, and they get to see and discuss preliminary reporting results before the engineer leaves the site.

[Do you aspire to the C-suite or some other spot in upper IT management? Then bulk up your credentials around today's most pressing IT movement, digital business, at the InformationWeek IT Leadership Summit.]

2. Pictures speak volumes.

To evaluate, communicate, and educate a client about specific risks, engineers can now build graphs and charts in real-time with the data they collect on-site. They can produce a pump-test curve chart to evaluate the current operating performance of a fire pump, and they can graph the fire pump test against the design parameters, as well as previous tests, with corrections for speed.

3. Educate through video.

With immediate Internet access, risk engineers can reinforce loss prevention with informational videos. They can go to YouTube or a video library and show a video to illustrate what can be done -- or what the ramifications are if something is not done.

4. Access helpful apps.

If a client has concerns about how the local terrain poses risks to property, there's an app for that. To help explain various scenarios or observed risks, risk engineers can easily turn to other applications available on the Internet to help evaluate and illustrate possible risks, and they can share more information about how clients can improve their loss prevention efforts.

5. Strike up more conversations.

Risk engineers work closely with our clients. If they are spending less time inputting data or rifling through volumes of building codes to find needed information, they can spend more time talking with clients, offering guidance on loss prevention, and strengthening relationships.

Today, thanks to our mobile Risk Assessment Field App, there is more time for conversations about actions, safety strategies, and remediation approaches that can help protect property and employees. These conversations are further supported by other online tools and capabilities that this iPad tool offers. More risk engineers are leveraging technology to engage customers in a meaningful dialogue about loss prevention and property protection.

Dave Schmitz leads XL Group's Global Risk Engineering Team, a sector of its North America Property business, which provides property protection for large, complex commercial and industrial risks. He is based in Atlanta and can be reached at [email protected]. View Full Bio